O-rings (also known as packing joints) are gaskets that are donut-shaped and can be employed in static or dynamic applications. O-rings are one of the most frequent seals used in machinery around the world because they are simple to make, affordable, and dependable.

Steps to Designing an O-Ring

Select a material with the appropriate features and characteristics for the purpose.

The ability of an O-ring to survive the conditions it will be subjected to is an important consideration when choosing one.

Different O-ring materials can be utilized with different liquids and gases since some can tolerate the impacts of chemicals and oil, while others are unable. During the design phase, it is critical to consider and thoroughly examine the sorts of gases or liquids to which the O-ring may be exposed

The hardness of the O-ring must be appropriate for the application. The hardness of O-rings ranges from the softness of a rubber band to the hardened wheels of a shopping cart or conveyor.

The size of the groove or gland where the O-ring will be installed is an important consideration in its design. The cross-sectional (CS) dimensions of the O-ring, as shown in the chart below, are the deciding element when selecting the right O-ring.

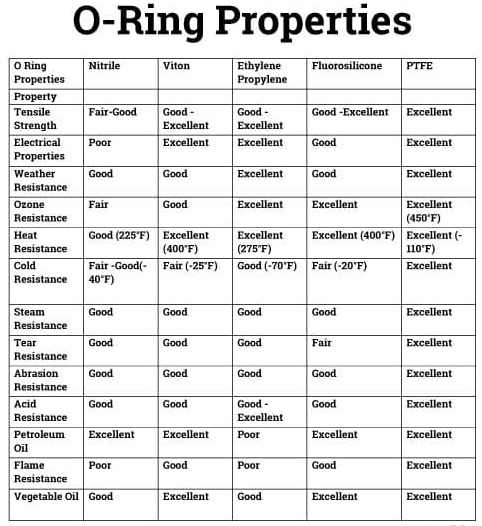

It is critical to select the suitable material for the O-rings application to ensure proper performance. Chemical compatibility, temperature resistance, and a variety of other factors influence the type of material used as well as its use. The most common elastomers used to make O-rings are PTFE, Nitrile (Buna), Neoprene, EPDM Rubber, Fluorocarbon (Viton), and Silicone, with silicone being utilized for high-temperature applications. The table below provides a brief overview of a few O-ring materials and their qualities. The materials that are blended into elastomers give them their performance and properties.

Chemical exposure, severe temperatures, and vibration are all factors that influence O-Ring elastomer selection. Custom compounds have been developed to fulfill stringent OEM and Tier 1 specifications, and they are constantly refined to meet biofuel and emissions regulations.

Sealing systems for valves, gas pumps, fittings, dispensers, and storage tanks must be able to endure extreme temperatures, toxic chemicals, and tremendous compression. Heat and chemical resistance are ensured by specialty compounds such as peroxide and triazine-cured perfluoro elastomers.